Less busywork. More breakthroughs.

SourceDay’s custom automation engine allows procurement teams to shift their energy from repetitive tasks to impactful initiatives.

Before SourceDay

A typical buyer manages hundreds (sometimes thousands) of POs per year. Every order requires multiple manual touchpoints across emails, phone calls, spreadsheets, and ERP edits.

- 88% of POs require 2+ interventions

- 35% of POs get buyer-initiated changes and 15% receive supplier-initiated changes

- 37% are late – triggering even more reactive work

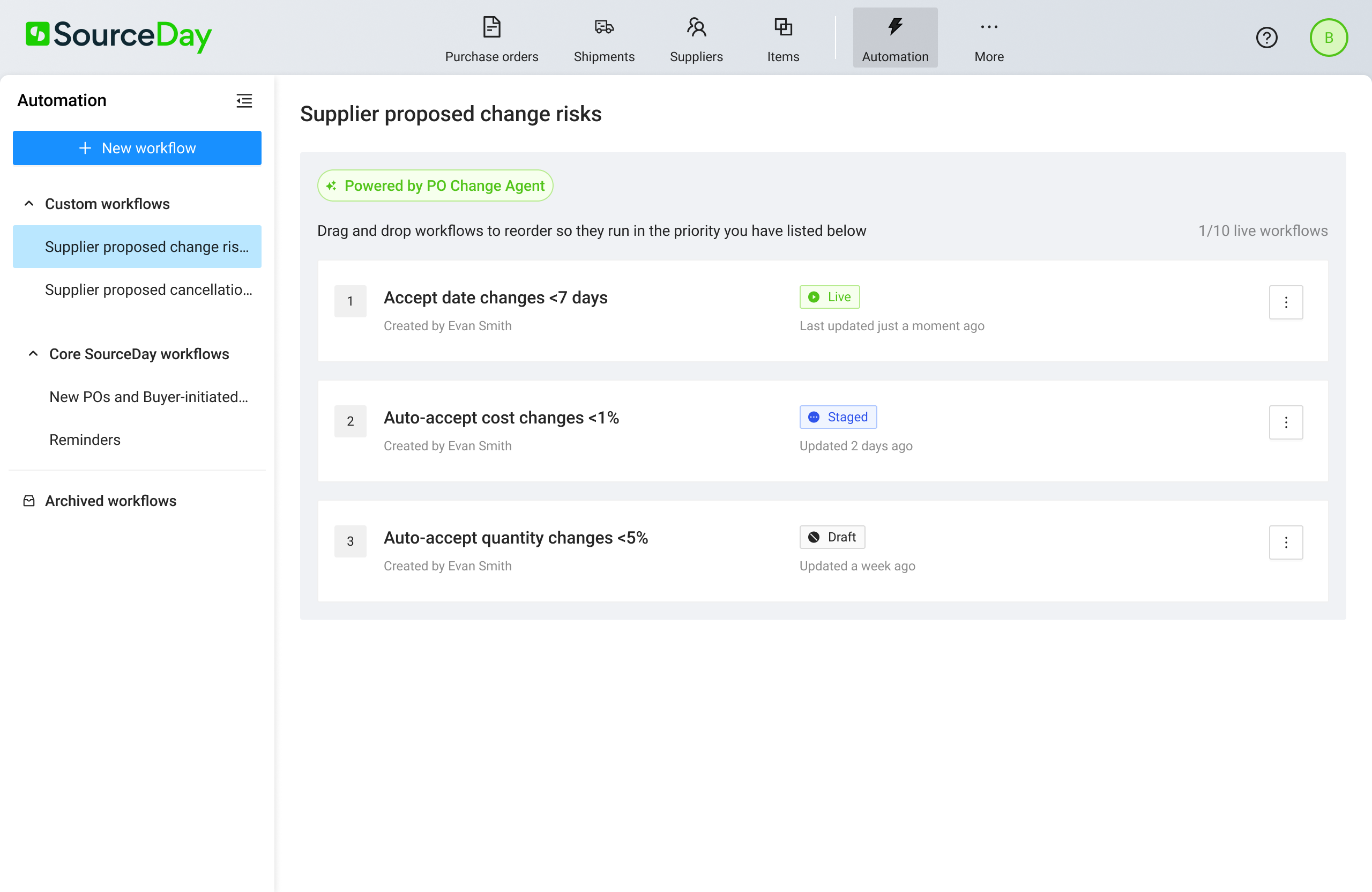

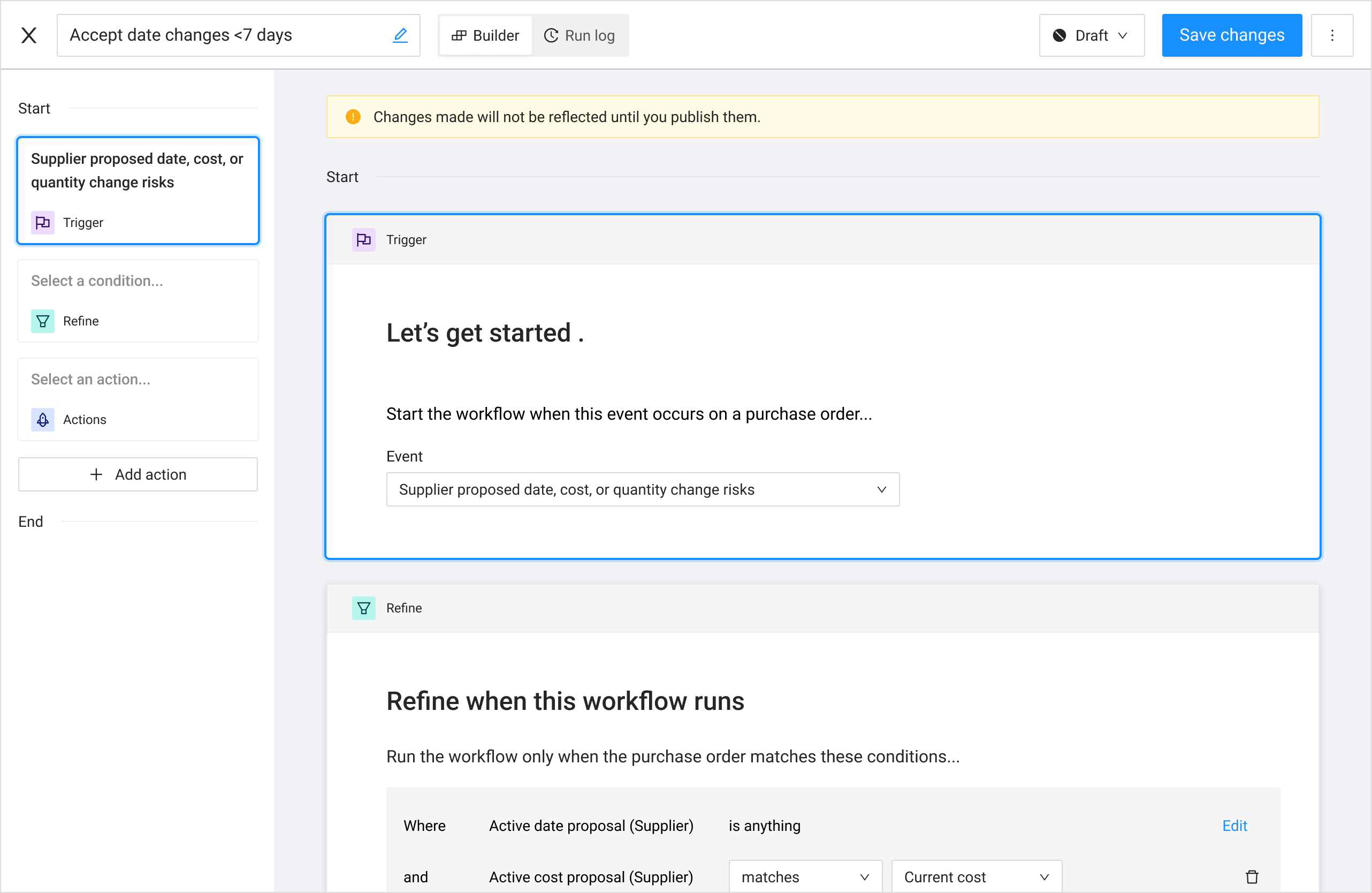

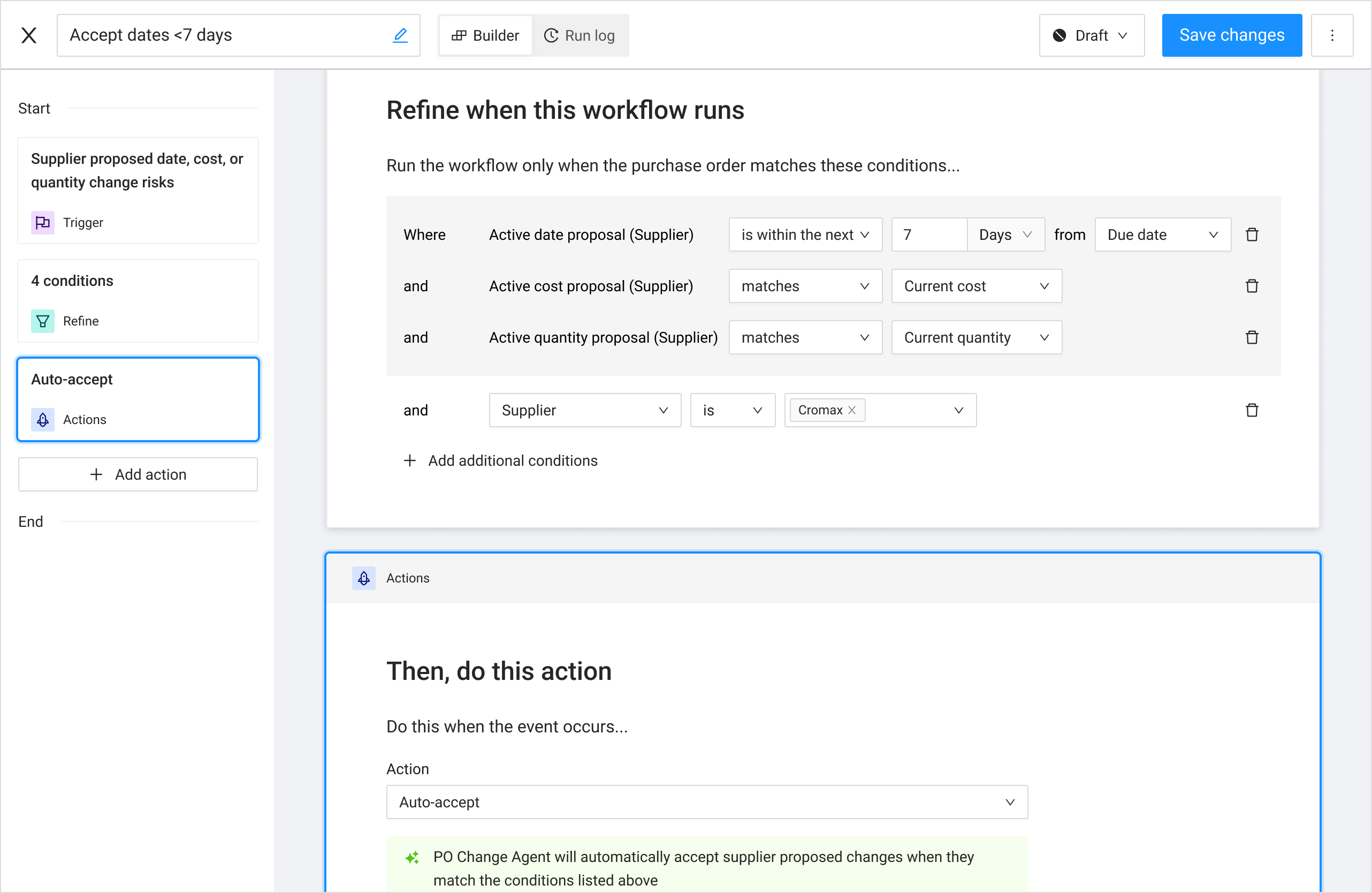

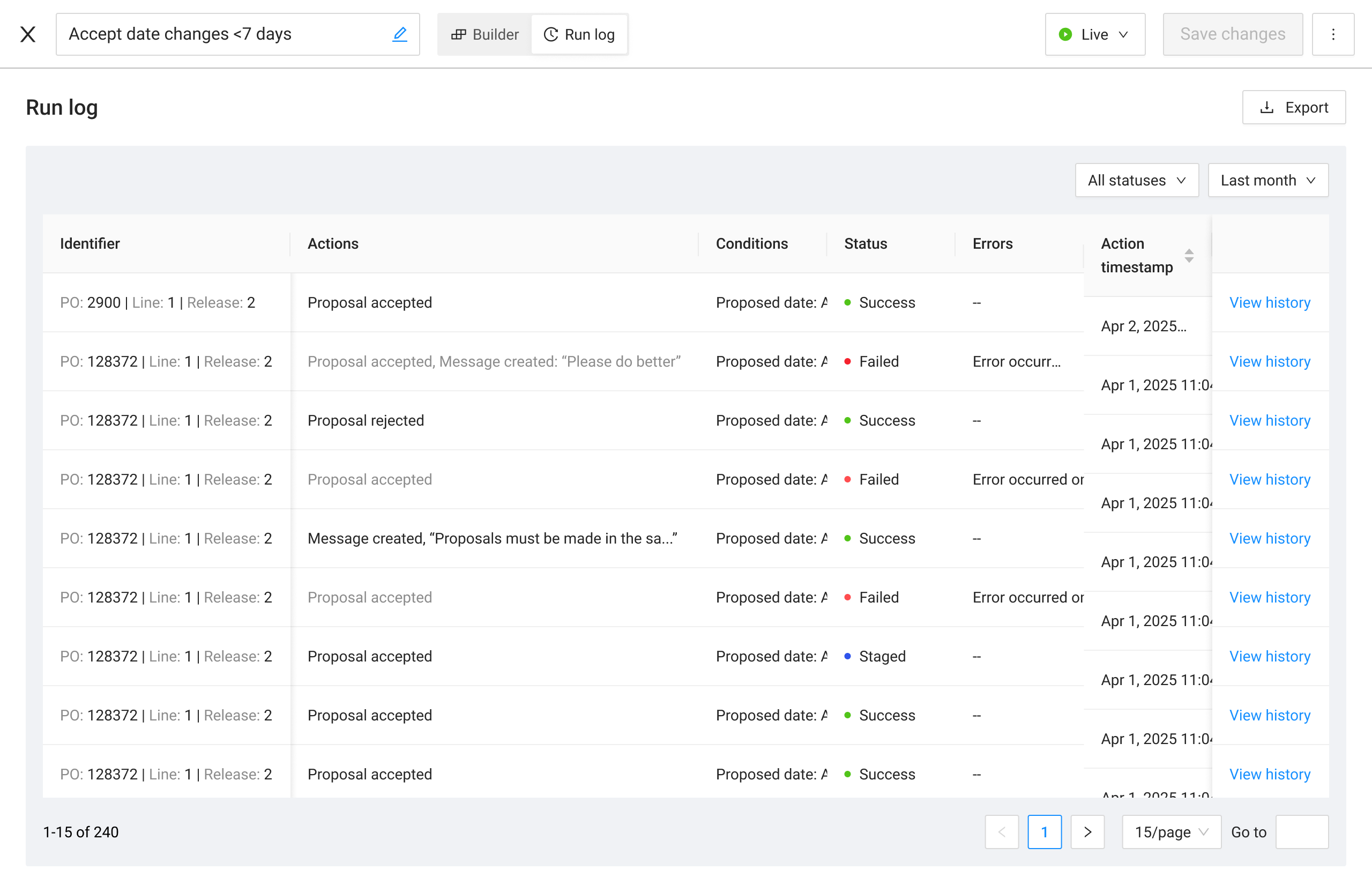

The opportunity with SourceDay automations

By automating routine interactions throughout the PO process, SourceDay helps buyers prioritize high-impact orders and reduce time spent on low-risk tasks.

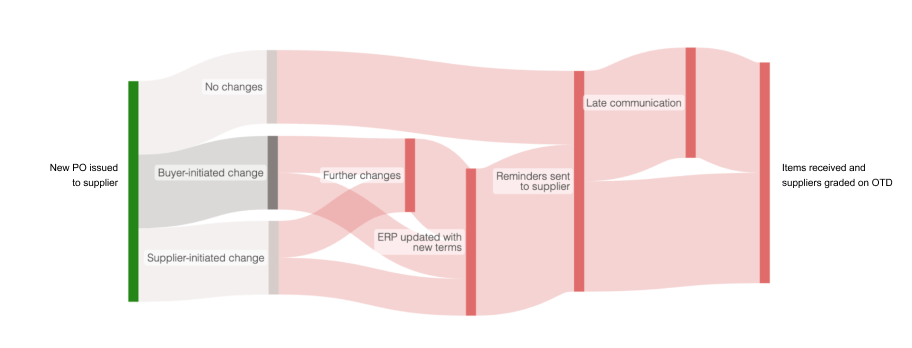

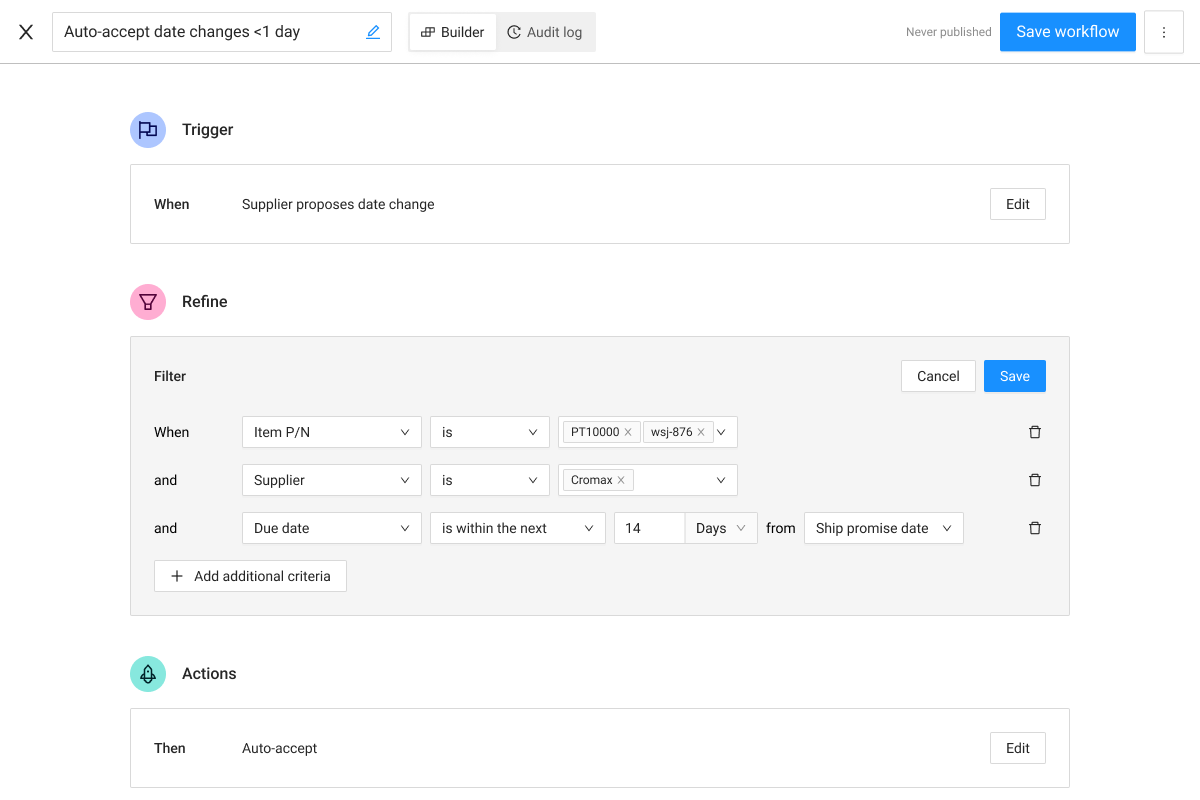

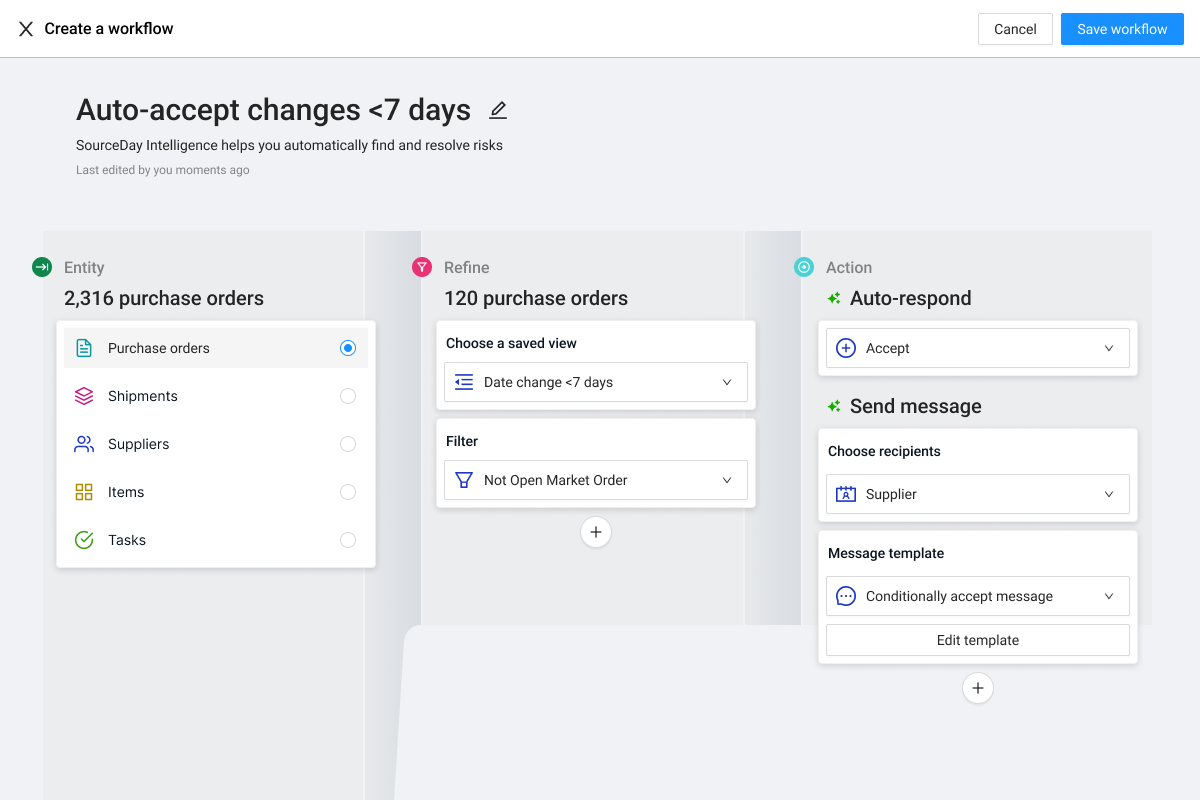

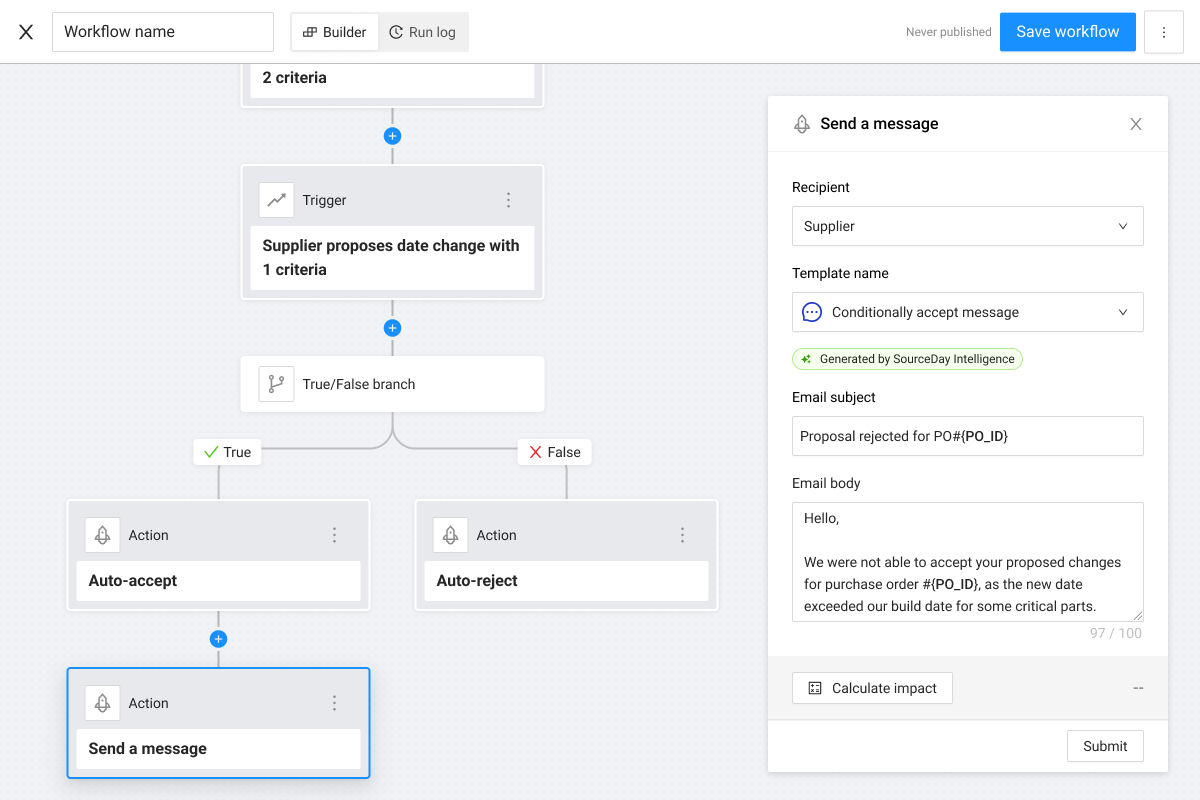

Early concept 1

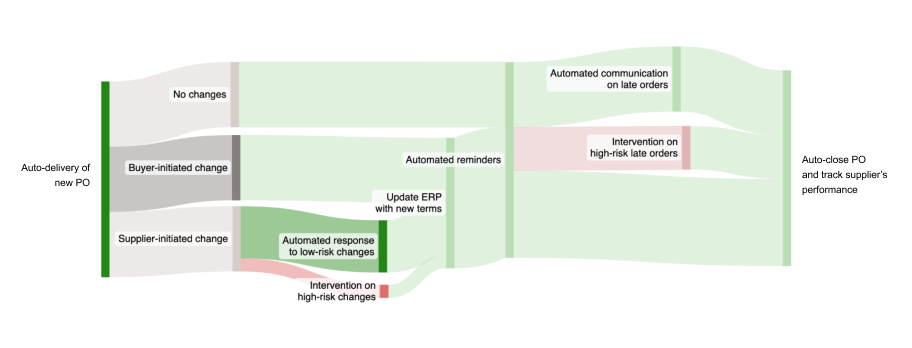

Early concept 2

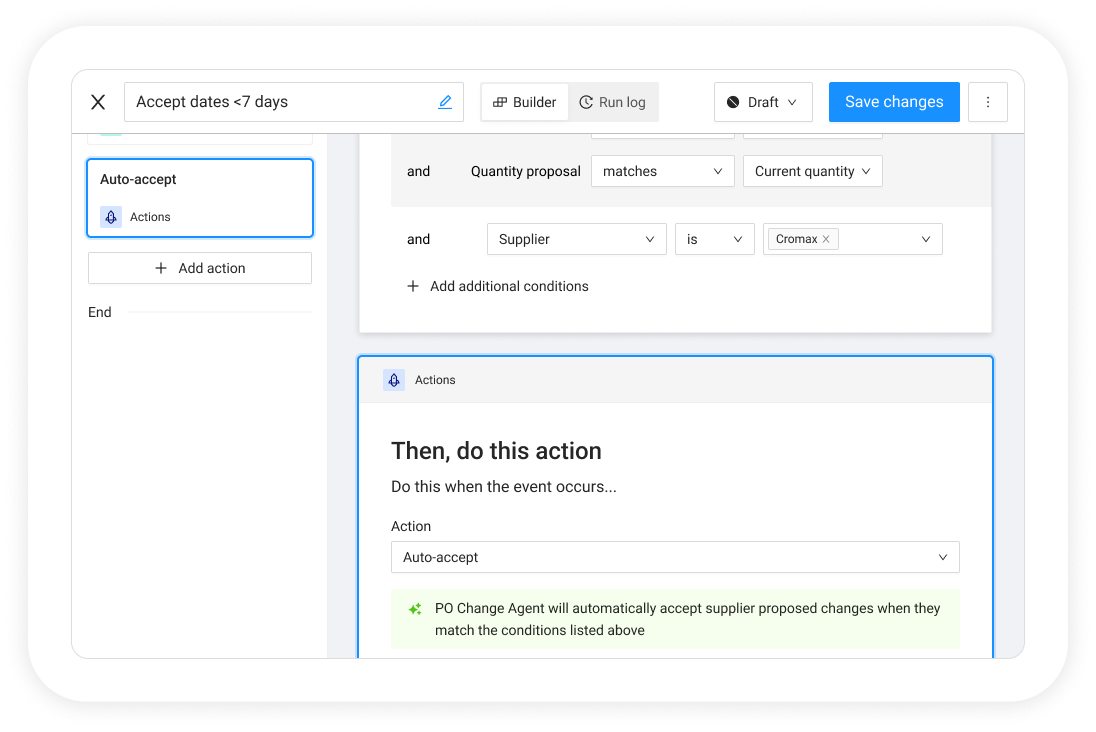

Early concept 3

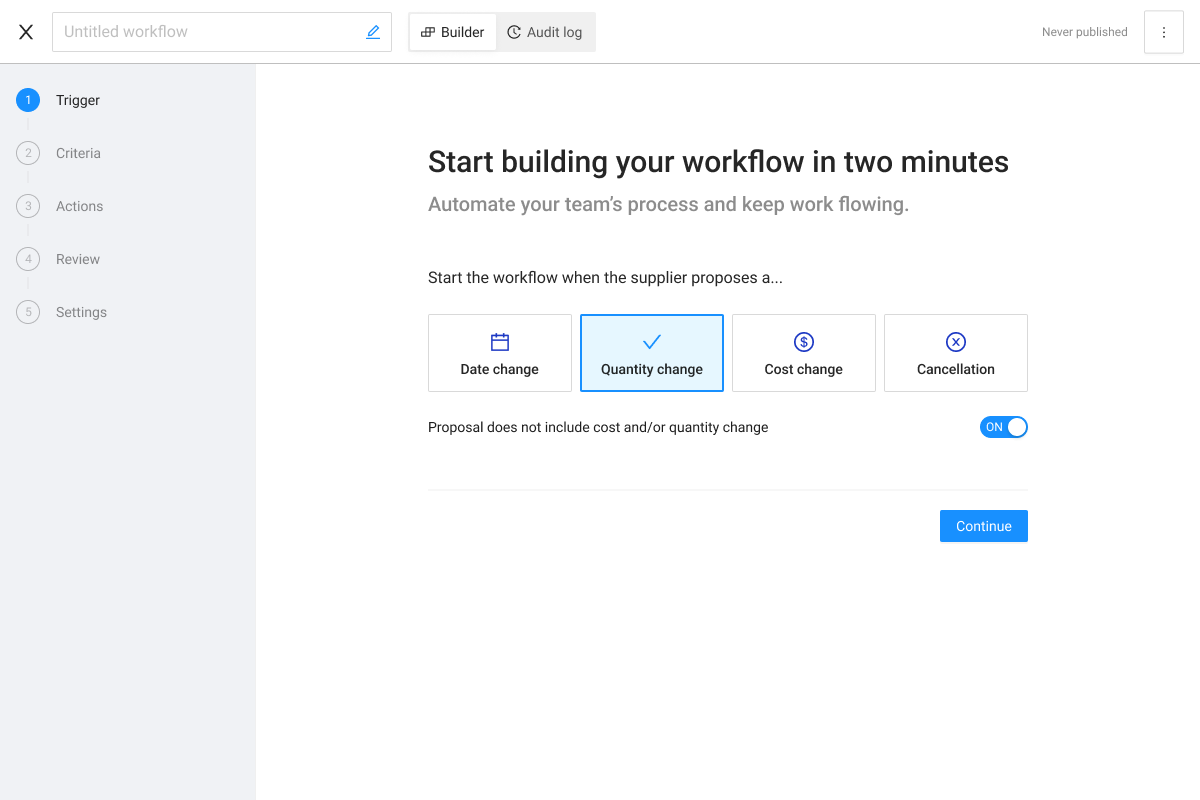

Early concept 4